01 May Micro-molded ‘ice cube tray’ scaffold is next step in returning sight to injured retinas

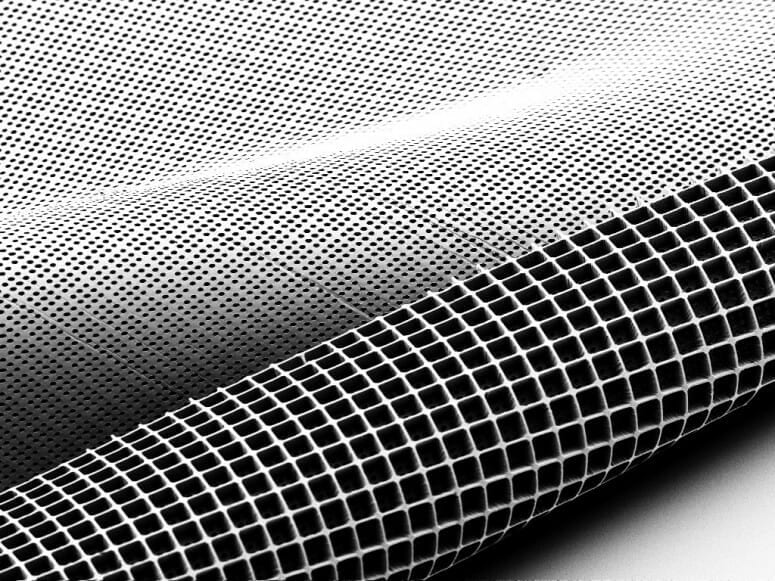

This electron microscope image of the new “scaffolding” for growing and implanting retinal cells shows the ice cube tray-shaped reservoirs that hold cells and cylinder-shaped holes in the bottom layer, which provide channels for maturing photoreceptors to make contact with a patient’s retinal tissue. COURTESY OF THE MA LAB

Tens of millions of people worldwide are affected by diseases like macular degeneration or have had accidents that permanently damage the light-sensitive photoreceptors within their retinas that enable vision.

The human body is not capable of regenerating those photoreceptors, but new advances by medical researchers and engineers at the University of Wisconsin–Madison may provide hope for those suffering from vision loss. They described their work today in the journal Science Advances.

Researchers at UW–Madison have made new photoreceptors from human pluripotent stem cells. However, it remains challenging to precisely deliver those photoreceptors within the diseased or damaged eye so that they can form appropriate connections, says David Gamm, director of the McPherson Eye Research Institute and professor of ophthalmology and visual sciences at the UW School of Medicine and Public Health.

“While it was a breakthrough to be able to make the spare parts — these photoreceptors — it’s still necessary to get them to the right spot so they can effectively reconstruct the retina,” he says. “So, we started thinking, ‘How can we deliver these cells in a more intelligent way?’ That’s when we reached out to our world-class engineers at UW–Madison.”