08 Sep Taming ‘tubes: For computer chips, new technique puts carbon nanotubes squarely in their place

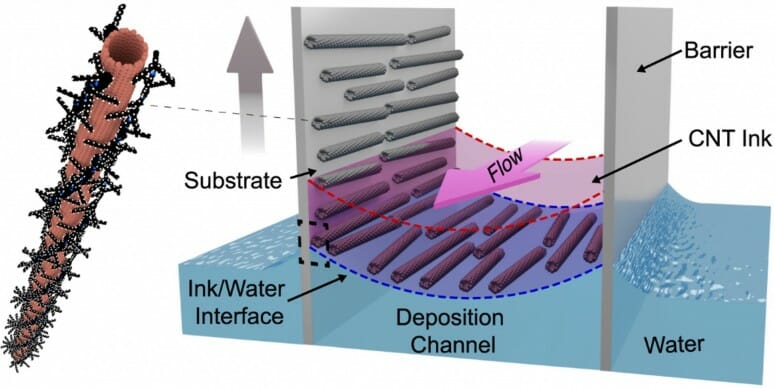

UW–Madison engineers have worked out a method to make orderly sheets of 2-dimensional carbon nanotubes by aligning them between layers of water and a solvent “ink.” COURTESY OF ARNOLD LAB

For half a century, researchers have regularly found techniques for shrinking silicon transistors, roughly doubling the number that can be crammed onto a computer chip and driving the transition from room-sized computers to smartwatches in the span of a lifetime.

These days, however, silicon transistors are so atomically small that soon it may not be possible to shrink them. That’s why researchers are investigating new, more efficient materials with the potential to replace silicon.

One leading candidate is carbon nanotubes, which are tiny, rolled-up pieces of the practically 2-dimensional wonder material graphene. When used as transistors, the nanotubes could be five times as energy efficient and five times faster than silicon. The problem is that working with the tiny tubes — just nanometers in diameter — is difficult. To be useful as transistors, they need to exhibit uniform electrical characteristics, be aligned in the same direction, and be closely, but not too closely, packed together.

Researchers have struggled to find techniques to precisely deposit the tubes, but engineers at the University of Wisconsin–Madison have discovered a new method of aligning the nanotubes by turning them into 2D liquid crystals. They described their research in the journal Science Advances.

“In this new technique we are able to align carbon nanotubes across industry scales,” says Katherine Jinkins, first author on the paper.

“In as little as 40 seconds, we can coat an entire 4-inch wafer with a uniform array of highly aligned carbon nanotubes,” she says. “That fills a void that has existed in the carbon nanotube community for almost 30 years.”

The technique was a serendipitous discovery. While trying to understand some previous research, the team deposited nanotubes suspended in a solvent over a layer of water. But the researchers noticed that the nanotubes began to self-organize and align at the interface between the liquids.

“We didn’t understand why, so this became the focus of four years of research by Katy to get to the bottom of it,” says Arnold. “Once we understood what was going on, then it could be engineered into a process that might be useful to industry.”