08 Apr UW–Madison researchers develop better way to make painkiller from trees

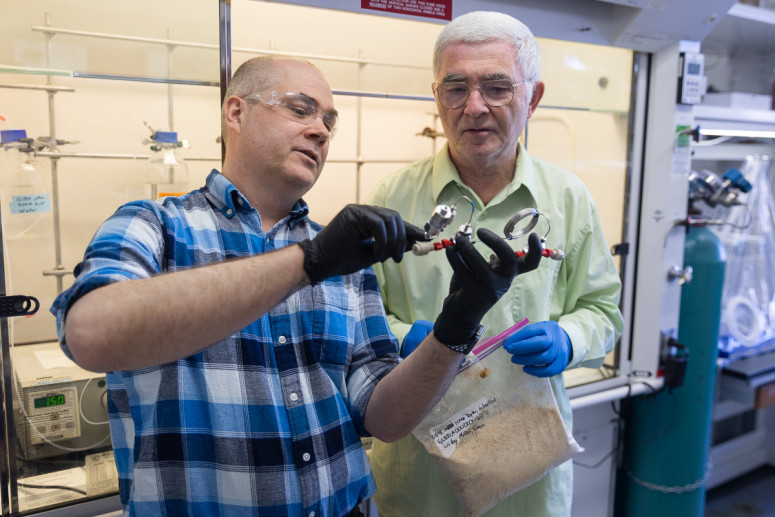

Scientists Steve Karlen and Vitaliy Tymokhin look over a reactor they used for their research on converting biomass into paracetamol.

Scientists at the University of Wisconsin–Madison have developed a cost-effective and environmentally sustainable way to make a popular pain reliever and other valuable products from plants instead of petroleum.

Building on a previously patented method for producing paracetamol – the active ingredient in Tylenol – the discovery promises a greener path to one of the world’s most widely used medicines and other chemicals. More importantly, it could provide new revenue streams to make cellulosic biofuels — derived from non-food plant fibers — cost competitive with fossil fuels, the primary driver of climate change.

“We did the R&D to scale it and make it realizable,” says Steven Karlen, a staff scientist at the Great Lakes Bioenergy Research Center who led the research published recently in the journal ChemSusChem.

Paracetamol, also known as acetaminophen, is one of the most widely used pharmaceuticals, with a global market value of about $130 million a year. Since it was introduced in the early 1900s, the drug has traditionally been made from derivatives of coal tar or petroleum.