03 Oct UW Researchers Help Uncover How to 3D-Print One of the Strongest Stainless Steels

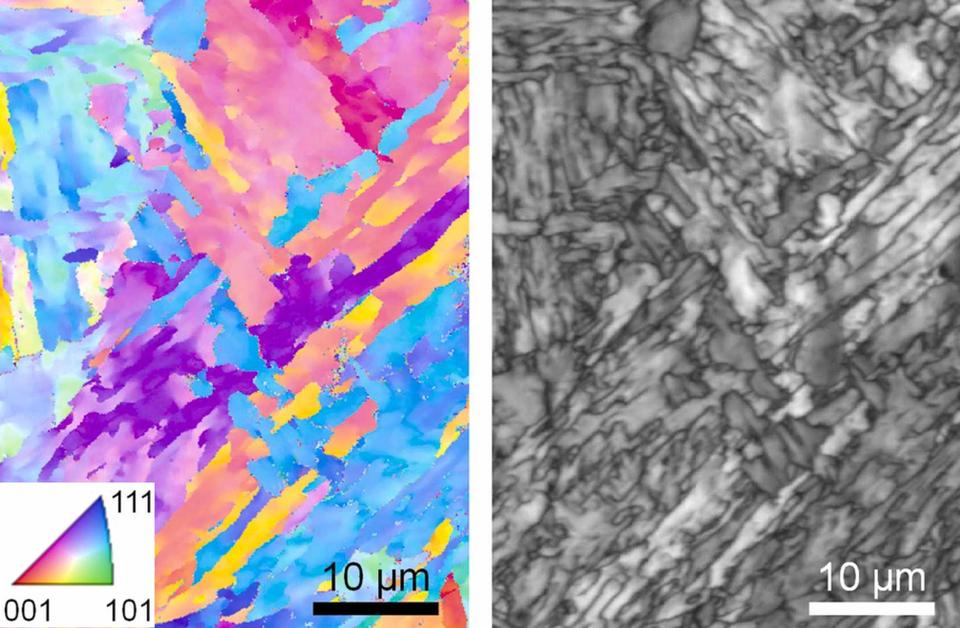

A microscopic image of 3D-printed 17-4 stainless steel. The colors in the left-side version of the image represent the differing orientations of crystals within the alloy. Credit: Q. Guo/University of Wisconsin-Madison

High-energy X-rays lit a path forward.

For airliners, cargo ships, nuclear power plants and other critical technologies, strength and durability are essential. This is why many contain a remarkably strong and corrosion-resistant alloy called 17-4 precipitation hardening (PH) stainless steel. Now, for the first time ever, 17-4 PH steel can be consistently 3D-printed while retaining its favorable characteristics.

A team of researchers from the National Institute of Standards and Technology (NIST), the University of Wisconsin-Madison and Argonne National Laboratory has identified particular 17-4 steel compositions that, when printed, match the properties of the conventionally manufactured version. The researchers’ strategy, described in the journal Additive Manufacturing, is based on high-speed data about the printing process they obtained using high-energy X-rays from a particle accelerator.

The new findings could help producers of 17-4 PH parts use 3D printing to cut costs and increase their manufacturing flexibility. The approach used to examine the material in this study may also set the table for a better understanding of how to print other types of materials and predict their properties and performance.